do you know what to include in your plan?

It's Finally Friday!!!

Last week was a much needed vacation with the family and this week we're back at it. As a matter of fact, I'm getting ready to head home from the National Environmental Health Association (NEHA) AEC in Nashville, Tennessee.... but more about that later!

Full disclosure; my Other Half has been helping me with bringing you “That Food Safety Guy” with her tech savviness and ability to make the website and social media posts look pretty. She was researching content ideas and was getting frustrated looking for a generalized Food Safety Plan.

She wanted to know if HACCP was a food safety plan? Well ... no. It is part of one. This simple response sparked quite the conversation (and frustration on her end)… So lets help simplify the problem.

Disclaimer: There are over 3000 authorities in the US alone that handle food safety. Each product is going to need its own plan. As such, there is no “One size fits all” plan. What we have are guidelines to help the manufacturer or retailer identify what needs to be in their program. If you are looking to set a plan in place for your facility, product, or restaurant, check with all of the authorities that will have jurisdiction over you. Find the conflicts early and get those authorities to sign of on any compromises. Local authorities usually have an appeal process for processes that conflict.

A good place to start is with a basic food safety plan. The Plan should contain:

In general, these documents should address:

HACCP or HARPC should be part of your process in developing these documents.

HACCP stands for Hazard Analysis and Critical Control Points and has been the standard since the 60’s. HACCP is based on guidelines suggested by CODEX and looks at the 3 primary hazards that contaminate food (Biological, Chemical, and Physical). It strives for prevention or elimination of those sources. HACCP is voluntary but may be a requirement of your downstream customers or certification bodies. HACCP has 12 steps (and principles).

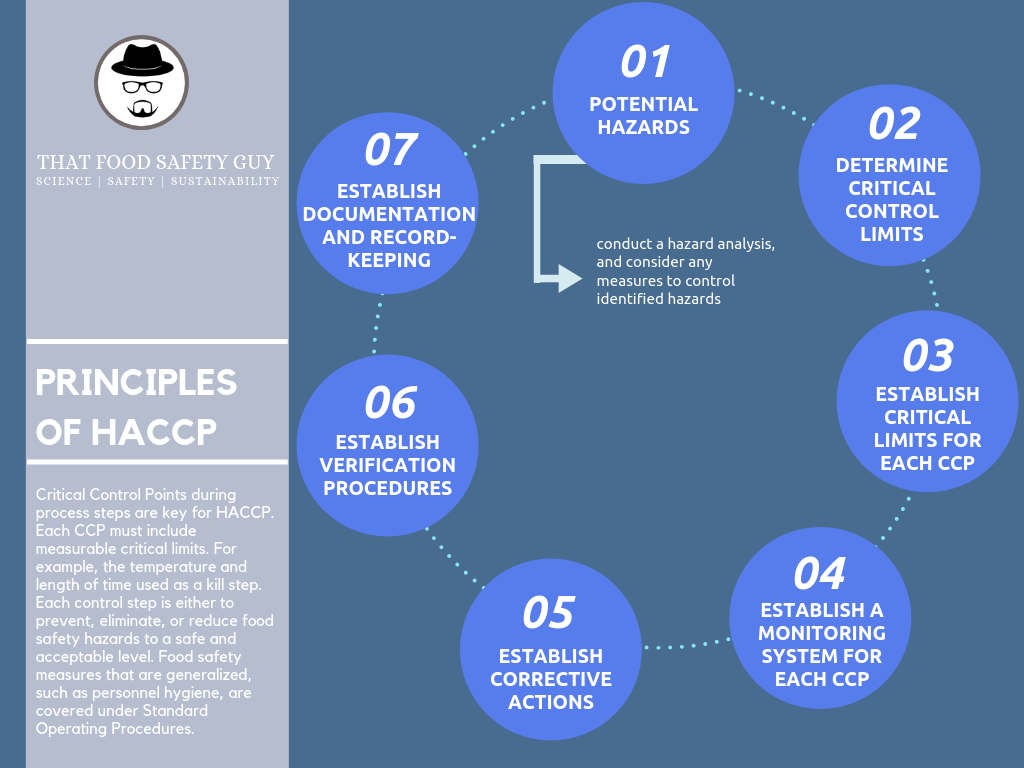

Critical Control Points during process steps are key for HACCP. Each CCP must include measurable critical limits. For example, the temperature and length of time used as a kill step. Each control step is either to prevent, eliminate, or reduce food safety hazards to a safe and acceptable level. Food safety measures that are generalized, such as personnel hygiene, are covered under Standard Operating Procedures. The Steps of HACCP The 5 steps to a HACCP Plan The 5 steps to a HACCP Plan

1. Assemble the multidisciplinary HACCP team

2. Describe the product 3. Identify its intended use 4. Construct a flow diagram 5. Conduct on-site confirmation of the flow diagram, and draw up the plant schematic The Principles of HACCP

6. List all potential hazards associated with each step, conduct a hazard analysis, and consider any measures to control identified hazards (Principle 1)

7. Determine Critical Control Limits (Principle 2) 8. Establish Critical Limits for each CCP (Principle 3) 9. Establish a monitoring system for each CCP (Principle 4) 10. Establish corrective actions (Principle 5) 11. Establish verification procedures (Principle 6) 12. Establish documentation and record-keeping (Principle 7)

Then there is HARPC (Hazard Analysis and Risk-Based Preventive Controls). HARPC is more of an upgrade to HACCP and is a requirement under the Food Safety Modernization Act (FSMA). It is the FDA’s baby and they have a ton of information on their website. The big differences are that it covers WAY more potential hazards (radiation, natural toxins, pesticides, drug residues, decomposition, parasites, allergens, unapproved food or color additives, naturally occurring hazards and intentionally and unintentionally introduced hazards) and what risk and science based Preventive Controls you put in place. PC’s should be adequate to “significantly minimize or prevent” known or foreseeable hazards for each type of food subject to the federal regulations.

7 Steps of HARPC 1. Assess the hazards—This includes the normal product-specific hazards, along with a broad range of other hazards (listed above) and facility-specific concerns such as food defense and emergency management issues. 2. Institute Preventive Controls—These include sanitation procedures for food contact points, staff hygiene training, environment monitoring, supplier verification and more. 3. Monitor effectiveness of the controls —Not all controls are measurable by critical limit numbers, but these Preventive Controls can be evaluated on a routine basis.

4. Establish corrective action measures—Recall plans may not seem preventive, but the critical steps between knowing something is wrong with a product and keeping it away from consumers’ hands should involve identifying and correcting the weak spots within the controls. The objective is to prevent occurrences of unsafe and nonconforming food product. 5. Establish verification measures—The process of verification ensures that the facility is effectively meeting its food safety standards on a consistent basis. 6. Follow proper and required recordkeeping—As with any FDA ruling, nothing is properly done until it’s recorded. 7. Reanalyze the plan once every 3 years, or when needed—When changes in process or product happen, HARPC plans should be reevaluated. BOOM! Done! See? Simple, Right? Let’s face it; this is what keeps guys like me employed. You must be passionate about it or it will just frustrate the hell out of you. Just ask my Lady Faire… She's still reeling from this information overload. Sláinte, James Science | Safety | Sustainability http://www.ThatFoodSafetyGuy.com Instagram▫️Facebook▫️Twitter @ThatFSGuy

2 Comments

5/28/2020 09:52:19 am

Reply

6/30/2020 04:55:00 am

You have explained in great detail. Very helpful article. Thanks for sharing.

Reply

Leave a Reply. |

James J. O'Donnell, iiiI'm THAT guy; the one who is going to keep you informed, make you laugh, make you think, and sometimes... I'm sure, I'll even make you shake your head. If you've been following me on Social Media, we've been building up to this for a while... CategoriesARCHIVESSeptember 2019

August 2019

July 2019

June 2019

May 2019

|

RSS Feed

RSS Feed